What is a gas spring?

A gas spring consists of a cylinder tube with a piston rod moving back and forth inside, equipped with a piston. The gas spring is filled with nitrogen, allowing it to come under (high) pressure depending on the required force and the limits of the gas spring itself. At the front (rod side), the cylinder tube is sealed with a guide through which the piston rod moves back and forth. At the rear (housing side), the cylinder tube is sealed with a bottom piece.

The pressure is equal on both sides of the piston because there is a flow channel in the piston, which also provides end damping for both the inward and outward strokes through a small amount of oil.

Replace your gas spring

Easily and quickly replace and order your current T-Technics gas spring with the article number. Replace your gas springCALCULATE YOUR GAS SPRING

Order your desired gas spring in a few simple steps using our configurator. Assemble your panel/hatch gas springCATALOGUE

The gas springs are custom-made and offer virtually unlimited possibilities. View catalogue

Assembly and use of gas springs

Gas springs are manufactured from high-quality components and therefore need to be mounted and used in a specific manner. Consider characteristics and/or restrictions regarding materials, temperatures, storage, vibrations, free movement, lateral forces, mounting methods, as well as usage and/or loading methods. For a further/complete explanation of restrictions, please refer to our “Gas Spring User Manual“.

For your own safety, it is absolutely prohibited to make changes to gas springs by drilling, sawing, or welding. Additionally and explicitly mentioned here is that gas springs should never be cleaned (directly) with a steam cleaner or high-pressure washer. Once gas springs have been ordered and/or filled for you, they cannot be exchanged or returned.

Feel free to ask for our advice regarding any different installation or other questions.

Design and specifications

The T-Technics gas pressure and gas traction springs, as well as special products, are custom-made in-house for you. For larger quantities, the gas springs can be provided with your own name and article number.

The oil inside a gas spring provides the end damping for both the compression and extension strokes. If desired, we can increase this damping before filling and even decrease it for certain types.

All gas springs are refillable, meaning that the extension force can still be increased afterward by T-Technics. However, there are also models available with a valve through which the extension force can be decreased afterward.

T-Technics can also equip certain types of gas springs with a provision for you to release the pressure yourself. This means T-Technics fills the gas springs to their maximum pressure (depending on the type). Then, you can install the gas spring “on the job” and release the pressure until the system works properly. Please refer to the gas spring type “Controlspring” for this.

Calculation

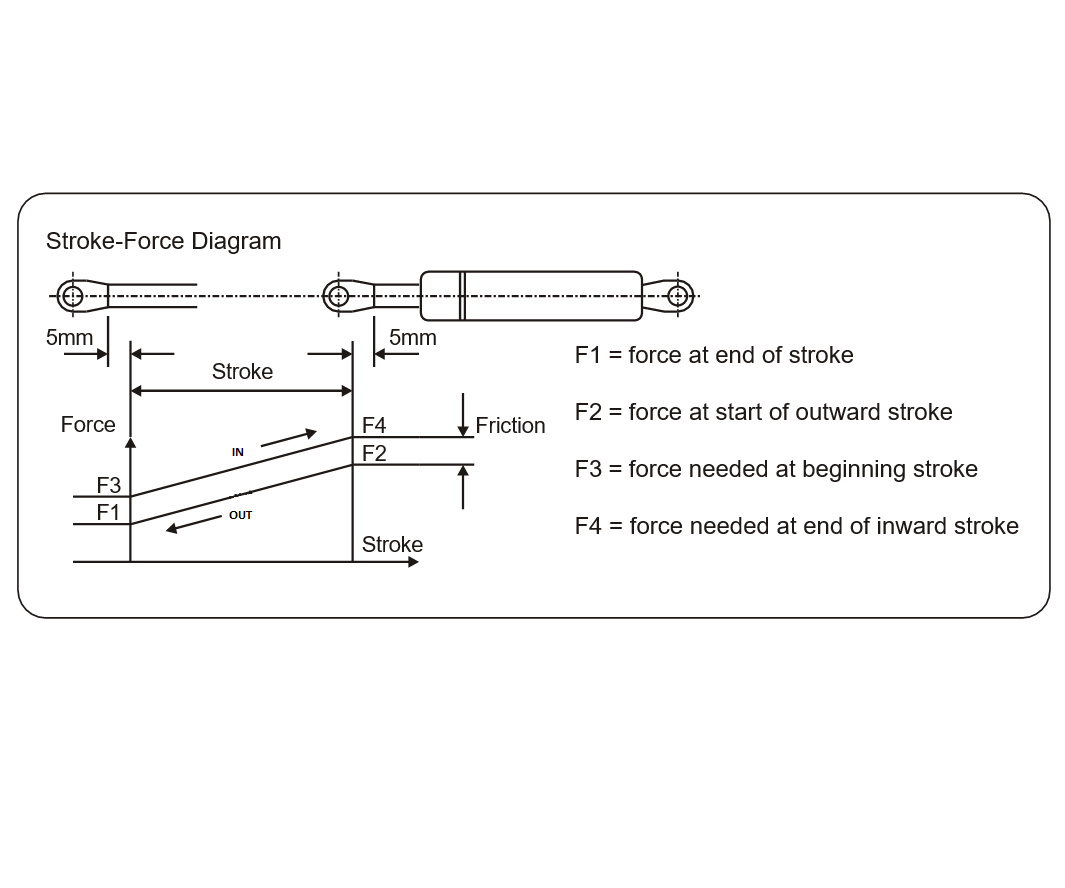

Because the gas springs at T-Technics are filled ‘in-house’, any desired extension force F1 can be ordered. This, of course, is within the limits of the gas spring type. This helps to somewhat avoid longer delivery times. The extension force F1 of the gas spring is determined by multiplying the filling pressure by the surface area of the piston rod.

The extension force F1 is measured by compressing the rod by 10 mm and allowing it to return by 5 mm and is expressed in Newtons (N). Refer to the table below for this.

Progressiveness

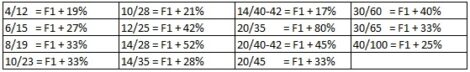

Due to T-Technics having its own production facility for gas springs, T-Technics can, in principle, realize any combination by changing the piston rod/cylinder tube combination. T-Technics can provide further information on this. The resulting pressure increase in the gas spring, when using the full stroke length, due to its operation, is referred to as “progressiveness”. This varies by gas spring type, namely:

Progressiveness of gas pressure springs:

Progressiveness of gas traction springs:

![]()

Airax Gas Springs

The Airax gas springs are standardly supplied with a black-coated or painted cylinder housing, providing excellent corrosion resistance. The resulting pressure increase in the Airax gas spring due to its operation is referred to as “progressiveness”. This varies by gas spring type, namely:

Progressiveness of gas pressure springs:

![]()

Tolerances in pressure

The pressure tolerances apply to T-Technics and Airax gas springs. The gas spring can be filled with the desired pressure according to customer wishes, but of course within the lower and lower limits applicable to the specific gas spring. There is a certain tolerance on the pressure (F1) with which the gas spring is filled, namely:

- F1 = 20N – 50N, tol. = +/-10N

- F1 = 50N – 250N, tol. = +/-20N

- F1 = 250N – 750N, tol. = +/-30N

- F1 = 750N – 1500N, tol. = +/-50N

- F1 = 1500N – 2500N, tol. = +/-100N

- F1 = 2500N en meer, tol. = +/-250N

The tolerances on the length dimensions apply to T-Technics and Airax gas springs. The tolerances on length dimensions are +/-2 mm.

Gas springs user manual

For a detailed description of safe usage and other important aspects such as warranty, environmental awareness, recycling, and modifications to the gas spring, we kindly refer you to the user manual.

- Warranty: To ensure your peace of mind, we offer a warranty period.

- Environmental awareness: Our company is committed to sustainability.

- Recycling: Discover how to safely dispose of and recycle your gas spring at the end of its lifespan.

- Modifications to the gas spring: Important information regarding possible changes in material types and designs.

For detailed information, we cordially invite you to consult the user manual.